When it comes to measuring fluid flow, particularly in industrial applications, Venturi tubes have long been a popular choice. Their ability to measure flow accurately and reliably has made them a staple in various industries, including oil and gas, water treatment, and chemical processing. But what about high-pressure applications? Can Venturi tubes handle the demands of such environments? In this blog, we’ll explore the capabilities of Venturi tubes in high-pressure scenarios and discuss their effectiveness as flow meters, particularly as Venturi tube flow meters.

- Understanding Venturi Tubes and Their Functionality

- Venturi Tube Flow Meters: How Do They Work?

- High-Pressure Applications: The Challenges

- Venturi Tubes in High-Pressure Applications: Analyzing Their Performance

- Advantages of Venturi Tubes in High-Pressure Applications

- Limitations and Considerations

- Can Venturi Tubes Handle High-Pressure Applications?

Understanding Venturi Tubes and Their Functionality

Before diving into their high-pressure applications, it’s important to understand what Venturi tubes are and how they work. A Venturi tube is a device that measures the flow rate of a fluid by constricting its flow in a specific section of a pipeline. This constriction causes a pressure drop, which is then measured to determine the flow rate based on the Bernoulli principle. The Venturi effect, named after Italian physicist Giovanni Battista Venturi, explains how the velocity of a fluid increases while its pressure decreases when it flows through a constricted section of pipe.

Key Components of a Venturi Tube

A typical Venturi tube consists of three main sections:

- Converging Section: This section gradually narrows the diameter of the tube, causing the fluid velocity to increase and its pressure to decrease.

- Throat: The narrowest part of the tube, where the fluid velocity reaches its maximum, and the pressure is at its lowest.

- Diverging Section: This section gradually widens, allowing the fluid to decelerate and recover some of its lost pressure.

These three sections work together to measure fluid flow accurately. The pressure differential between the inlet and the throat of the Venturi tube is proportional to the flow rate, allowing for precise calculations.

Venturi Tube Flow Meters: How Do They Work?

Venturi tube flow meters utilize the pressure differential created by the Venturi tube to measure the flow rate. When fluid enters the converging section, it speeds up, and the pressure decreases. At the throat, where the diameter is smallest, the velocity is highest, and the pressure is lowest. As the fluid exits into the diverging section, it slows down, and some pressure is recovered.

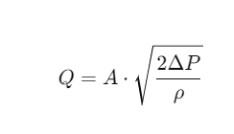

The flow rate (Q) can be calculated using the pressure difference (ΔP) between the inlet and the throat, along with the density of the fluid (ρ) and the cross-sectional area of the throat (A) using the equation:

This equation shows the relationship between the flow rate and the pressure differential, demonstrating the Venturi tube’s ability to provide accurate measurements even in varying pressure conditions.

High-Pressure Applications: The Challenges

High-pressure applications present unique challenges that require specialized equipment to handle the stresses involved. High pressure can lead to increased stress on piping and measurement devices, potential leak points, and safety hazards if not properly managed. Therefore, the question arises: can Venturi tubes, particularly Venturi tube flow meters, handle these conditions?

Factors to Consider in High-Pressure Environments

- Material Strength: In high-pressure environments, the material used for the Venturi tube must withstand the forces exerted by the fluid. Stainless steel, titanium, and other high-strength alloys are commonly used in such scenarios to ensure durability and longevity.

- Construction Quality: The quality of construction and the precision in the design of the Venturi tube are critical. Any imperfections can lead to measurement inaccuracies or even structural failures under high pressure.

- Installation and Maintenance: Proper installation and regular maintenance are essential in high-pressure applications to ensure the Venturi tube operates as intended. Improper installation can cause turbulence, leading to inaccurate readings and potential damage to the tube.

Venturi Tubes in High-Pressure Applications: Analyzing Their Performance

Venturi tubes are well-suited for high-pressure applications for several reasons:

- Robust Construction: Venturi tubes are designed to be highly robust, often made from materials that can withstand high pressures and temperatures. This makes them ideal for use in demanding environments where other flow measurement devices might fail.

- Accurate Flow Measurement: Venturi tubes provide highly accurate flow measurements even in high-pressure scenarios. The tube’s design minimizes energy loss and allows for precise readings, which is crucial in high-pressure applications where small errors can lead to significant issues.

- Wide Range of Applications: Venturi tubes are versatile and can be used with various fluids, including gases, liquids, and steam. This versatility makes them suitable for different high-pressure applications across multiple industries.

- Low Maintenance Requirements: Venturi tubes have no moving parts, reducing the risk of mechanical failure. This design aspect also means they require minimal maintenance, which is a significant advantage in high-pressure environments where equipment downtime can be costly.

Industries and Applications

Venturi tubes are commonly used in several high-pressure applications across various industries:

- Oil and Gas: In the oil and gas industry, Venturi tube flow meters measure the flow of crude oil, natural gas, and other fluids under high pressure. They are particularly useful in offshore drilling and pipeline monitoring, where high-pressure conditions are prevalent.

- Water Treatment: In water treatment plants, Venturi tubes measure the flow of water and other fluids. High-pressure applications include the distribution of treated water through pipelines, where accurate flow measurement is crucial.

- Chemical Processing: The chemical industry often deals with high-pressure systems where accurate flow measurement is essential for maintaining process efficiency and safety. Venturi tubes are ideal for measuring the flow of various chemicals and gases under high pressure.

- Power Generation: In power plants, especially those using steam as a working fluid, Venturi tubes measure steam flow under high pressure. Accurate measurement is crucial for maintaining efficient power generation and avoiding potential damage to equipment.

Advantages of Venturi Tubes in High-Pressure Applications

Venturi tubes offer several advantages in high-pressure environments:

- Durability: Venturi tubes’ robust construction makes them highly durable. They can withhold the stresses associated with high-pressure applications without deformation or failure.

- High Accuracy: Venturi tube flow meters provide accurate flow measurements even under high-pressure conditions, which is critical in applications where precision is essential.

- Versatility: Venturi tubes can handle a wide range of fluids, including corrosive and abrasive materials, making them suitable for various high-pressure applications.

- Low Pressure Drop: Venturi tubes are designed to minimize pressure drop across the measurement point, which is crucial in high-pressure systems where maintaining pressure is important for process efficiency.

- Long Service Life: Venturi tubes typically have a long service life due to their rugged design and lack of moving parts, reducing the need for frequent replacements and minimizing downtime.

Limitations and Considerations

While Venturi tubes are highly effective in high-pressure applications, there are some limitations to consider:

- Initial Cost: Venturi tubes can be more expensive upfront than other flow measurement devices. However, their durability and low maintenance requirements often offset this initial investment over time.

- Installation Requirements: Proper installation is critical to ensure accurate measurements. In high-pressure applications, this may require specialized fittings and flanges, which can add to the cost and complexity.

- Space Requirements: Venturi tubes require a certain length of straight pipe upstream and downstream to ensure accurate flow measurement. In some high-pressure systems, this may not always be feasible due to space constraints.

Can Venturi Tubes Handle High-Pressure Applications?

In conclusion, Venturi tubes, particularly Venturi tube flow meters, are highly capable of handling high-pressure applications. Their robust construction, high accuracy, and versatility make them an ideal choice for industries requiring precise flow measurement under challenging conditions. While there are some considerations, such as cost and installation requirements, the benefits often outweigh the drawbacks, making Venturi tubes a reliable and effective solution for high-pressure environments.

Sebastian is an accomplished author with a passion for storytelling. His works span various genres, from thrilling mysteries to heartfelt romance novels. With a keen eye for detail and a knack for character development, Sebastian weaves engaging narratives that captivate readers and transport them to new worlds.